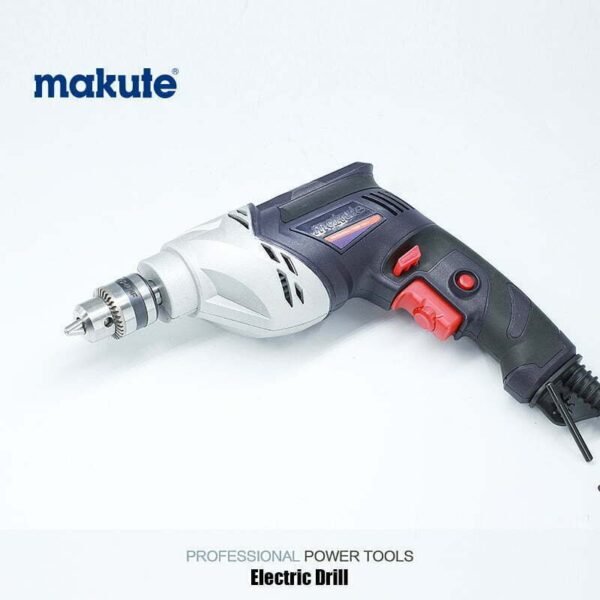

Power source: electric cable

Voltage: 220-240 volts

Frequency: 50/60 Hz

Power: 300 A

Cable length: 1.4 meters

Certifications: ISO9000

|

The question |

The answer |

|

What is an inverter welding machine? |

Inverter welding machine:

It is an advanced welding machine that uses IGBT technology to convert electrical current into a highly efficient and precise welding current, producing a strong and clean weld with lower energy consumption. It is characterized by its small size, light weight, ease of portability, and precise current control, and is suitable for various types of metals. |

|

What are the advantages of inverter welding machine? |

High efficiency:

It consumes less energy compared to traditional machines, which reduces operating costs.

Excellent welding quality: Produces a strong, clean, and smooth weld, ensuring the durability and strength of welded joints.

Ease of use and portability: It features a compact design and light weight, making it easy to carry, transport and use in various locations. |

| What are the main uses of inverter welding machines?

|

Maintenance workshops:

Ideal for various repairs on iron and steel in maintenance shops.

Construction works: Used in the construction of metal structures and projects that require strong and reliable welding.

|

| What are the most important tips for buying an inverter welding machine? | Determine your needs first:

Project type and nature of work: Whether it's a home project, a workshop, or a heavy industrial project, this determines the power of the machine required.

Metal Type: You must choose a machine that is suitable for the types of metals you will be welding, especially steel and aluminum.

Work size: Do you need a machine for light duty or heavy duty continuous work?

Technical specifications of the machine Current intensity (amps): Choose an amperage that is adequate for the type and thickness of the material you will be welding. Inverter machines allow precise control of the amperage for perfect results.

Duty Cycle: It indicates how well a machine can operate continuously without overheating. The higher the duty cycle at maximum current, the better the machine is for heavy-duty work.

Power source: Ensure the machine is compatible with the electrical supply available at the work site, whether it is 220 volts for homes or 380 volts for industrial applications. |